Assembly

Assembly

In aerospace, "sub-assembly" refers to the partial assembly of components or units before the final assembly of aircraft or spacecraft. This process involves assembling and testing multiple components or subsystems before integration into the final product.

Assembled Components

- Raw Material

- General Steel

- Special Processes

- Black Oxide Treatment

- Component Size

- 2,000mm (W) × 1,800mm (H) × 500mm (D)

Aerospace Component Assembly / GSE and Jig Manufacturing

For both commercial and government aircraft, we handle the design, material procurement, component processing, assembly, and quality assurance of aerospace components, GSE, and jigs. We manufacture high-precision, high-quality products, including fastening, sewing, bonding, sealing, welding, and surface treatments, for a wide range of components made from metal, resin, and fiber, tailored to their specific characteristics and requirements.

Assembly Support Services

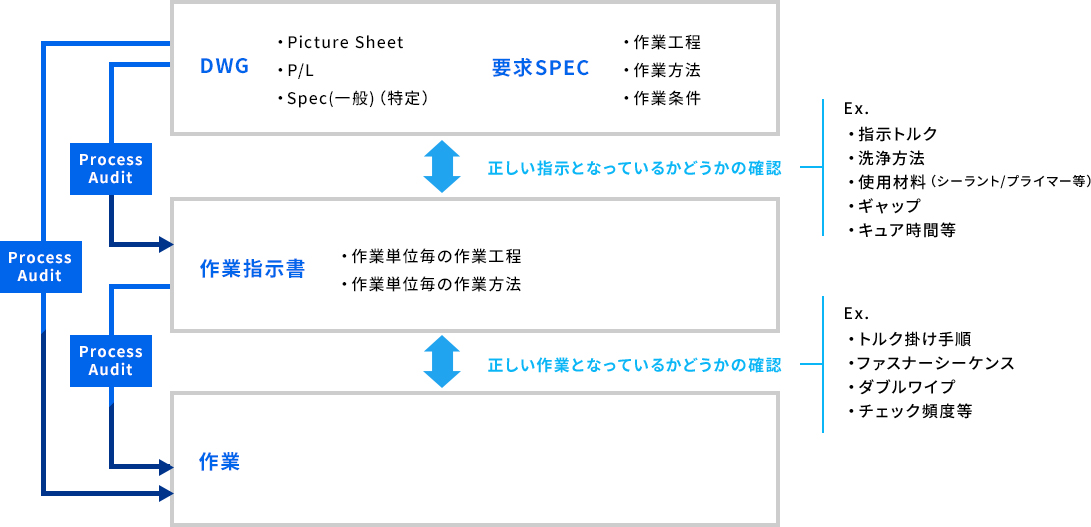

01 Identifying Potential Non-Conformities Through Process Audits

02 Interface Measurement Services

[Equipment Used] High-Precision Non-Contact 3D Measuring Machine

[Measurement Areas] Wing Tip / Nacelle / Wing-Body Junction

03 Seal Adhesion Inspection Services

Seals Inside and Outside the Main Wing Tank

- Inspection Points

- Approximately 18,000 Points per Wing

- Measurement Time

- Approximately 80-90 Hours per Wing

04 Foreign Object (FO) Inspection Services

Foreign Object Residue Inspection After Aqua Wash and Pre-Delivery Aircraft Foreign Object Check (FOC)