TECHNOLOGY

- Kaga Sangyo Co., Ltd. Top

- TECHNOLOGY

‘At KAGA SANGYO we aim to fulfil our vision of ‘Proactive Creativity’ and ‘Customer Satisfaction’ by developing new technical solutions to solve our Customer’s problems. Here are two examples where our innovation has delivered significant cost reductions and improvements for our Customers.’

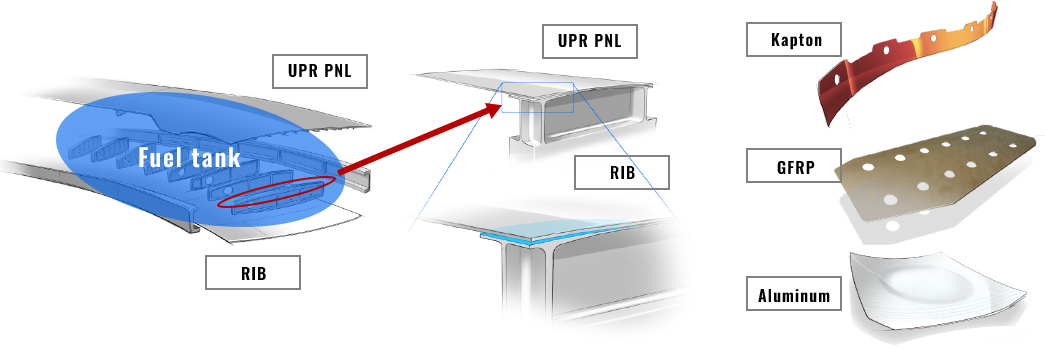

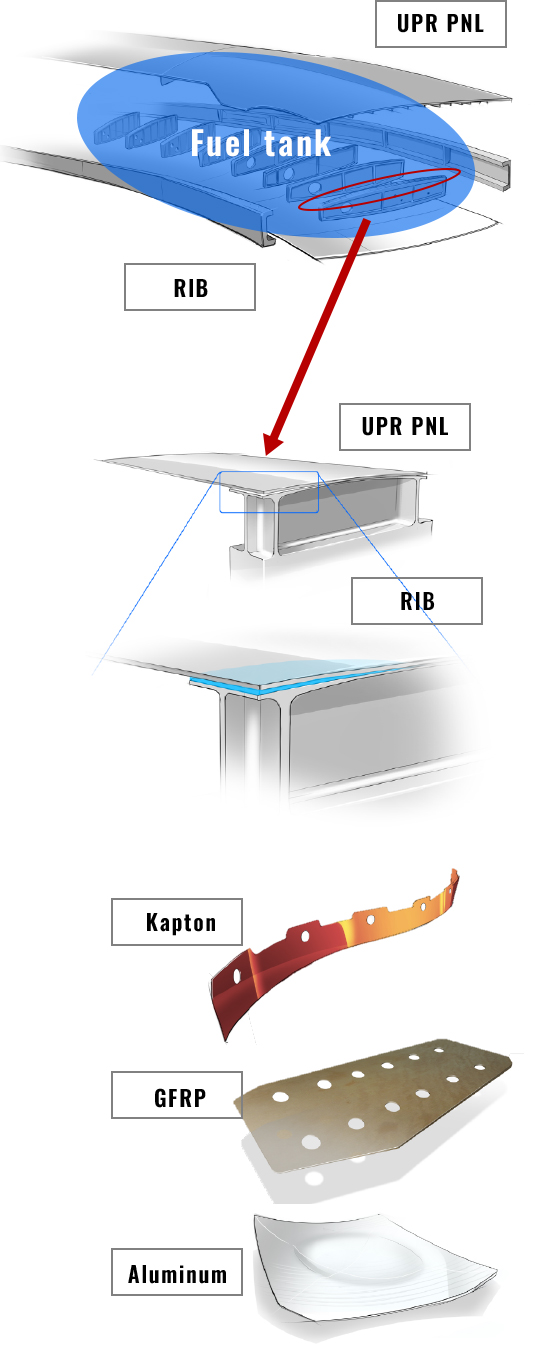

SHIM Products

Technology to achieve quick and highly efficient cutting of 3D shimsWe developed the technology to cut complex 3D surface shims that fill the gap between the wing panel (SKIN) and wing ribs (RIB) generated during the assembly of the main wing structure within the tight production cycle time required by the customer.

SHIM・・・

A SHIM is a very thin and often complex shape product made of resin or metal that is designed to accurately fill the gap to prevent the inevitable gap between the OML molding (Outer Mold Line) of a composite component and its mating component, to maintain the strength of the airframe and avoid generation of massive build stresses in assembly. This improves the life of the components in service.

KAGA

Technology

With conventional technology, during machine trimming of the SHIM material the drill tip often passes

through the work in the thickness direction to reach the inside of the support member. We addressed this

issue by developing proprietary position control technology so that the drill tip does not reach the

pallet surface, avoiding scrap and decreasing cycle times. We also installed a machining center in the

Customer’s plant to provide a superior level of responsiveness and meet the cycle time needs of the

Customer. This contributed to significant work process improvements for the Customer and the stabilization

of quality and production issues.

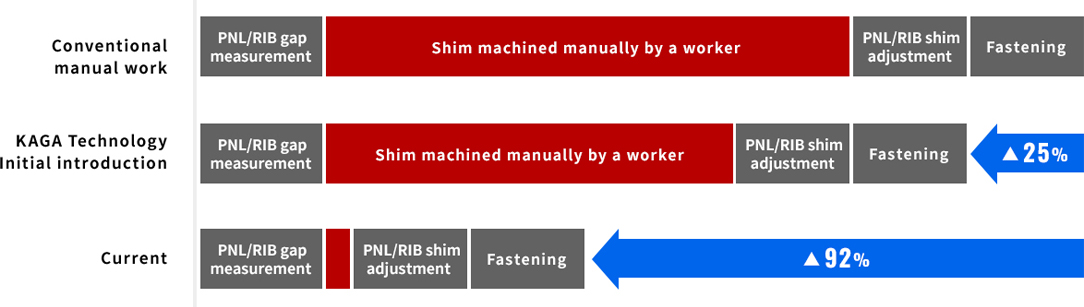

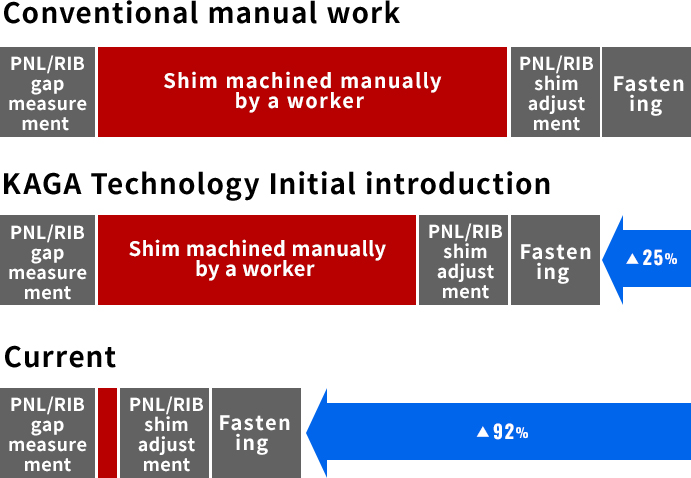

Specific improvement measures included switching to NC, creating a system for gap data input, and

adopting a machining automation program. We also created a kitting system and made other minor

improvements to benefit the Customer.

- ※Representative figures, not actual figures to protect Customer confidentiality.

- ※KAGA production capacity:2,600 shims per shipset → 31,200 shims per month

KAGA SANGYO developed a new shim machining process to drastically reduce assembly flow times and improve quality.

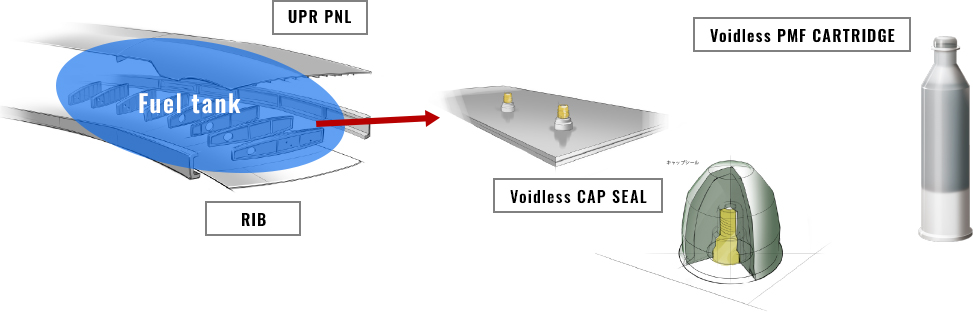

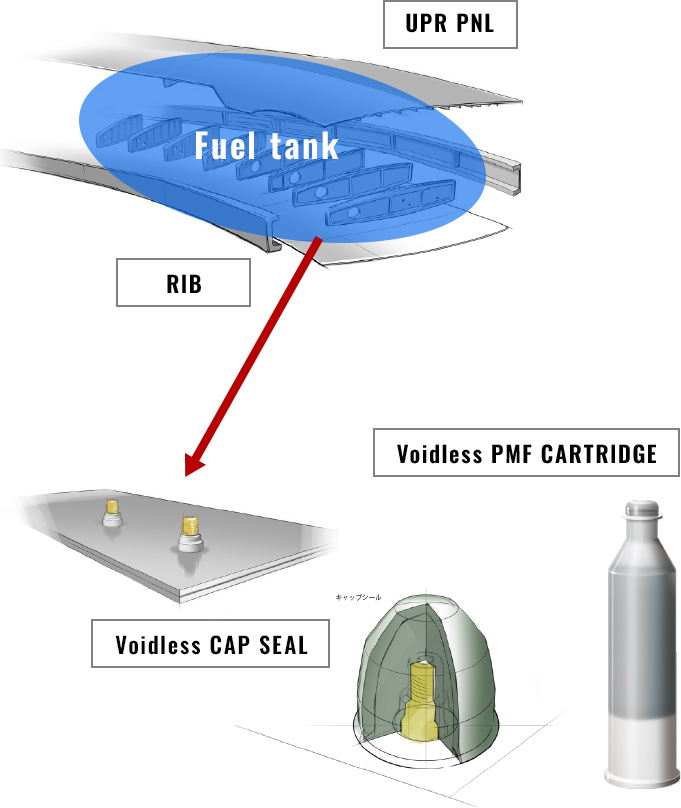

SEALANT Products

Technology to remove voids from sealants for EME countermeasures.KAGA SANGYO developed a new technology to agitate, defoam, fill and mold so that voids are not mixed into the high viscosity materials such as the sealant that is applied in fuel tank applications.

*Sealant material is…

Sealant is a material used to maintain airtightness in the aircraft’s fuel tank and to prevent sparking from lightning. Sealant is a critically demanding material because voids in the cured sealant product can compromise the aircraft protection system with the risk of aircraft accidents.

KAGA

Technology

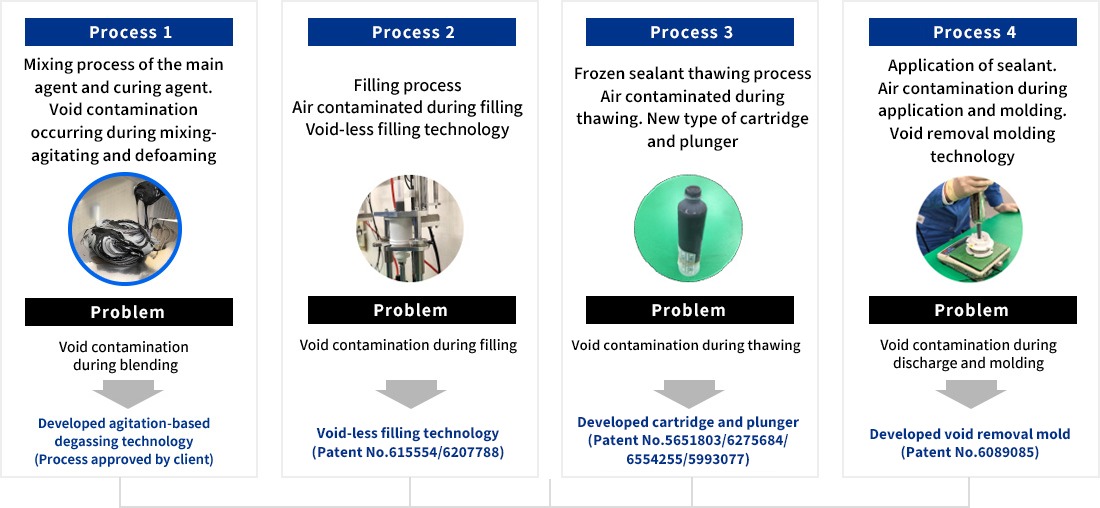

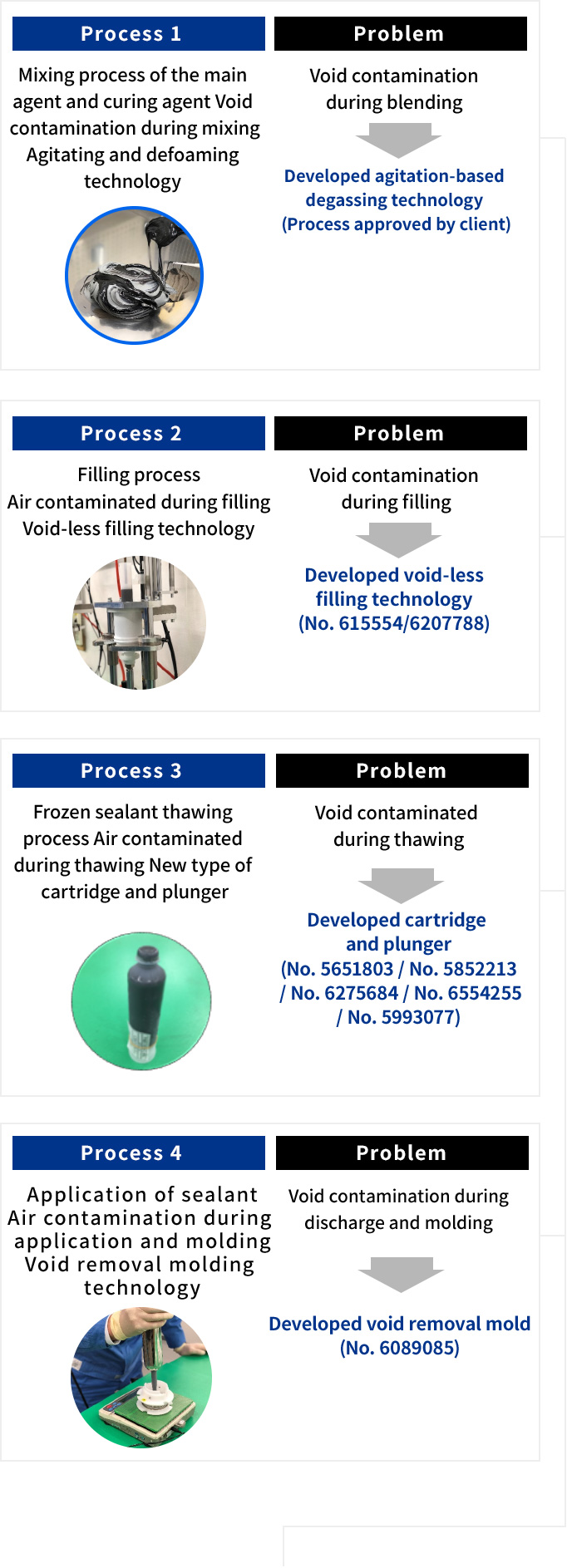

To address issues with conventional sealant technology, we developed new technology designed to remove

air during each manufacturing step and in the application process. We developed (1) vacuum defoaming

technology, (2) filling technology, and (3) a new type of cartridge and plunger.

These technologies contributed to deliver a higher level of quality, production stability and cost

reductions for the Customer’s operations as well as contributing to reduced costs for ancillary materials.

KAGA SANGYO’s understanding of the Customer’s use issues resulted in our ability to develop our proprietary technology to revolve each problem. We have Patents awarded for these technologies.

Developed new KAGA SANGYO technologies to solve each of the Customer’s problems