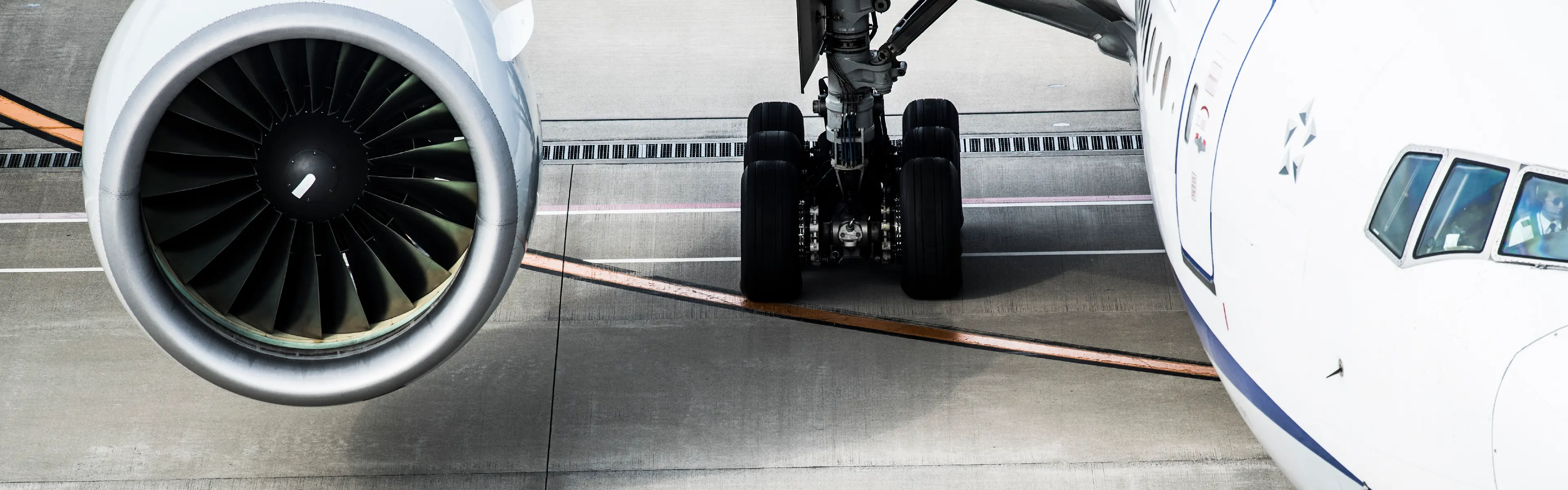

STRENGTH 01

Established a Nationwide Network of Over 170 Suppliers

As the first fabless company in the aerospace industry, we have established a unique network of over 170 suppliers nationwide. Based on customer requirements, we select the optimal processing partners and methods from our extensive supplier network, managing the entire process from planning to final product delivery. Our centralized management reduces the burden of per-process ordering, coordination, and indirect tasks, enabling reduced labor hours and costs. From small to large-scale production and from individual parts to assemblies, we meet all requirements with high-value-added EQCD (Quality, Cost, Delivery).