Manufacturing products with our "customer-first" philosophy is central to our business, and in order to make this a reality, we perform all planning, manufacturing, and quality assurance using the KAGA All-round Quality System described below.

HOW WE DO

- Kaga Sangyo Co., Ltd. Top

- HOW WE DO

- QUALITY ASSURANCE

QUALITY ASSURANCE

KAGA SANGYO is a professional aerospace manufacturer and supplier following our JIS Q 9100 (aerospace quality management system, AS9100 equivalent) certified quality assurance processes

KAGA SANGYO is JIS Q 9100 (AS9100 equivalent) certified and implements strict quality management throughout all our business. Our product inspection systems are continuously updated, and in addition to verifying product quality, also supports control of all outsourced processes. We use the very latest measurement systems in-house to ensure all our products meet the required accuracy and precision.

Quality Policies

Products that

meet the Customer

requirements

Products for Customers

that are reliable,

and at a reasonable price

Scope of Certification

Headquarters

Gifu Branch

Materials Center

KAGA SANGYO Oe Nishi In-Plant Facility

- Design and development, Production, Assembly of Precision Plastic and Metal Parts for Aircraft, Aerospace, Missile and Ground Support Equipment.

- Production and Assembly of Precision Plastic and Metal Parts for Marine applications.

KAGA All-round Quality System utilizing our long-established know-how

To accurately achieve the complex shapes required for aerospace parts, we have expanded our detail parts production and assembly know-how, developed over many years of work in the field, into a unique quality management system. Standardized workflows cover all processes from consulting drawings prior to ordering right through to process design and product inspection, all under our comprehensive and vigilant quality assurance system. We also undertake supplier inspections and functional inspections.

QUALITY ASSURANCE

At KAGA SANGYO we are rigorous in managing material sourcing, inspection, documentation and delivery according to customer requirements. We have established a dedicated "Material Center" to support optimizing this supply chain function through the robust and rapid supply of materials.

MATERIAL PROCUREMENT STANDARDS

- ANSI

- MIL

- AMS

- ASTM

- BS

- AS

- LN

- NF

- JIS

We have procured all types of material to multiple international standards, including titanium, tungsten, molybdenum copper, and alloy materials.

Pursuing ever-higher quality. Based on long-standing trust.

We have constructed a comprehensive non-destructive inspection system based on our diverse experience in parts machining and assembly. We provide non-destructive inspections compatible with a variety of international and Customer standards.

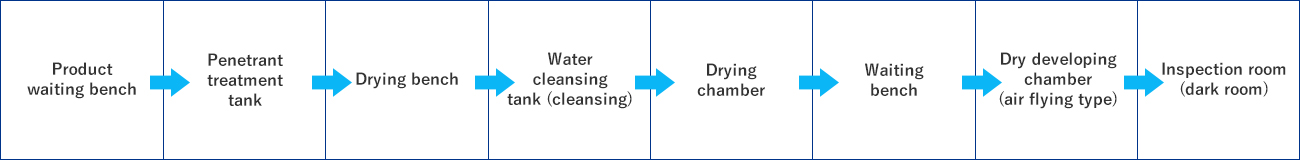

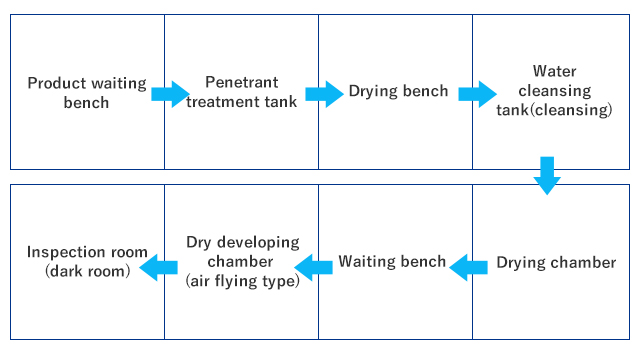

・Fluorescent penetrant flaw inspection

| Applicable standard | ASTM E-1417; Also compatible with other company standards. |

|---|---|

| Flaw detection method | TYPE I / METHOD A / Levels 2 or 3 / Form A, D |

| Carrying basket | 1,000 mm wide X 1,000 mm deep X 120 mm high |

|---|---|

| Penetrant treatment tank | 1,200 mm wide X 1,100 mm deep X 650 mm high (900L) |

| Water cleansing tank (cleansing) | 1,350 mm wide X 1,100 mm deep X 1,000 mm high |

| Drying chamber internal dimensions | 1,100 mm wide X 1,000 mm deep X 600 mm high *Only products small enough to fit within the dimensions of the drying/developing chamber can be treated. |

| Dry developing chamber internal dimensions | 1,100 mm wide X 1,000 mm deep X 600 mm high *Only products small enough to fit within the dimensions of the drying/developing chamber can be treated. |

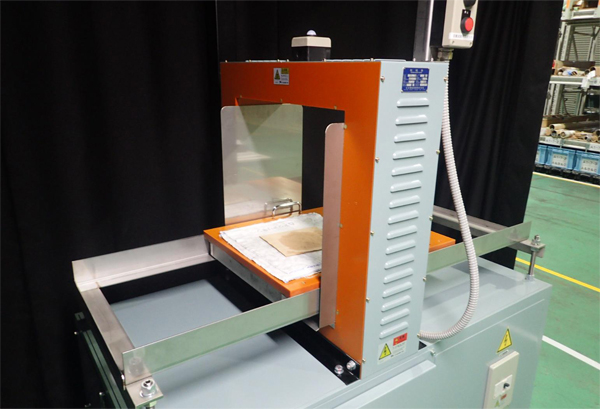

| Inspection room (dark room) | 1,100 mm wide X 1,000 mm deep X 900 mm high |

・Magnetic particle inspection

| Applicable standard | ASTM E-1417; Also compatible with other company standards. |

|---|---|

| Horizontal magnetic particle inspection equipment type | NQ-50TS |

| Penetrating demagnetization equipment type | LF-50S |

| Magnetizing current | DC current, AC three-phase current |

|---|---|

| Electrode pressure fixed time | DC100~9,000A |

| Electrode pressure fixed time | AC100~4,000A |

| Electricity conduction time | Capable of being freely set between 0 and 9.9 sec. |

| Electrode interval | 110~1,500mm |

| Coil inner circumference dimensions | 400mm |

| Target object weight | 20Kg or less |

・Demagnetization testing equipment

Demagnetizing current AC/DC current

- ・Alternating automatic attenuating demagnetization from AC 120 to 0A

- ・Distance attenuating demagnetization with a set output of AC 120A

- ・Direct current inversion automatic attenuating demagnetization from DC 120 to 0A

Electricity conduction time:

When AC, approx. 6 sec;

when DC, approx. 15~20

sec

Demagnetization capability:

When AC, 5,000 AT (max);

when DC, 10,000AT (max)

Demagnetizing coil dimensions:

Inner circumference of 500mm wide X 200mm deep X

500mm high

(Inner dimensions: 400 X 400mm)

・Alkaline cleansing equipment

Alkaline cleansing →cold water washing→hot water washing→air blow (dry)

Inner dimensions of each tank:

1,000mm wide X 1,000mm deep X 900mm high

Applicable cleansing liquid:

Super Bee 300LF (manufactured by Cee-Bee Chemical

Co., Ltd.)

NDT

Qualified Staff

NAS 410 level 3: 1 person

NAS 410 level 2: 2 people

(one of which is JIS Z 2305 level 2)

Mechanical Inspection Qualified Staff

1st grade ・・・ 1

3rd grade ・・・ 23

QM/QC

Qualified Staff

Grade 3 ・・・ 18